COURSE OVERVIEW

PROCESS & CHEMICAL ENGINEERING

OVERVIEW

| COURSE TITLE | : | PE0322 : Refrigeration System Commissioning, Operation and troubleshooting |

| COURSE DATE | : | Mar 04 - Mar 07 2024 |

| DURATION | : | 4 Days |

| INSTRUCTOR | : | Mr. Manuel Dalas Days |

| VENUE | : | Abu Dhabi, UAE |

| COURSE FEE | : | $ 4500 |

| Request For Course | ||

OTHER SCHEDULED DATES

| Date | : | Jun 03 - Jun 06 (4 Days) | Location | : | Istanbul, Turkey | Classroom Fee (US$) | : | $ 5000 | Course Info |

| Date | : | Sep 02 - Sep 05 (4 Days) | Location | : | Al Khobar, KSA | Classroom Fee (US$) | : | $ 4500 | Course Info |

| Date | : | Dec 16 - Dec 19 (4 Days) | Location | : | Dubai, UAE | Classroom Fee (US$) | : | $ 4500 | Course Info |

Course Description

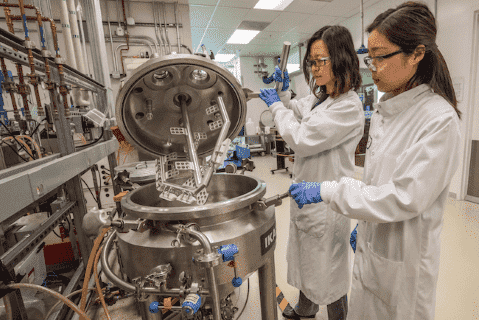

This practical and highly-interactive course includes practical sessions and exercises. Theory learnt will be applied using our state-of-the-art simulators. Refrigeration systems are common in the natural gas processing industry and processes related to the petroleum refining, petrochemical, and chemical industries. Several applications for refrigeration include NGL recovery, LPG recovery, hydrocarbon dew point control, reflux condensation for light hydrocarbon fractionators and LNG plants. Selection of a refrigerant is generally based upon temperature requirements, availability, economics and previous experience. For instance, in a natural gas processing plant, ethane and propane may be at hand; whereas in an olefins plant, ethylene and propylene are readily available. Propane or propylene may not be suitable in an ammonia plant because of the risk of contamination, while ammonia may very well serve the purpose. Halocarbons have been used extensively because of their non-flammable characteristics.This course is designed to provide participants with a detailed and up-to-date overview of refrigeration system commissioning, operation and troubleshooting. It covers the discuss mechanical refrigeration, refrigeration stages and condensing temperature, carryout horsepower and condenser duty estimation as well as design and operating considerations, apply considerations for vacuum refrigeration systems and identify the types of compressors, recognize mixed refrigerants, chillers an system controls as well as recognize absorption refrigeration and carryout principles of refrigeration processes. During this interactive course, participants will learn the illustrating of cryogenic processes and constant ? temperature refrigeration processes, identifying the need for refrigerant including optimum mixture composition, natural gas liquefaction process and cooling and liquefaction of air and its constituents, employing proper troubleshooting and problem solving processes, implementing the rules of thumb for troubleshooting and problem solving skills, applying gathering skills and interpersonal skills.

TRAINING METHODOLOGY

This interactive training course includes the following training methodologies as a percentage of the total tuition hours

LecturesWorkshops & Work Presentations

Case Studies & Practical Exercises

Videos, Software & Simulators

In an unlikely event, the course instructor may modify the above training methodology before or during the course for technical reasons.

VIRTUAL TRAINING (IF APPLICABLE)

If this course is delivered online as a Virtual Training, the following limitations will be applicable

| Certificates | : | Only soft copy certificates will be issued to participants through Haward’s Portal. This includes Wallet Card Certificates if applicable |

| Training Materials | : | Only soft copy Training Materials (PDF format) will be issued to participant through the Virtual Training Platform |

| Training Methodology | : | 80% of the program will be theory and 20% will be practical sessions, exercises, case studies, simulators or videos |

| Training Program | : | The training will be for 4 hours per day starting at 09:30 and ending at 13:30 |

| H-STK Smart Training Kit | : | Not Applicable |

| Hands-on Practical Workshops | : | Not Applicable |

| Site Visit | : | Not Applicable |

| Simulators | : | Only software simulators will be used in the virtual courses. Hardware simulators are not applicable and will not be used in Virtual Training |

RELATED COURSES

PE0221 : Operation of Process Equipment: Fired Heaters, Air Coolers, Heat Exchangers, Pumps, Compressors, Crude Desalter, Pressure Vessels & Valves

- Date : May 12 -May 16 / 3 Days

- Location : Dubai, UAE

- Course Details Register

PE0055 : Process Reactors: Operation, Troubleshooting, Start-Up & Shutdown

- Date : Jun 10 -Jun 13 / 3 Days

- Location : Abu Dhabi, UAE

- Course Details Register

PE0640 : Troubleshooting Process Operations

- Date : May 20 -May 24 / 3 Days

- Location : London, United Kingdom

- Course Details Register

PE0625 : Introduction to Polypropylene Technology

- Date : May 20 -May 23 / 3 Days

- Location : Istanbul, Turkey

- Course Details Register