COURSE OVERVIEW

MAINTENANCE, RELIABILITY & ROTATING EQUIPMENT ENGINEERING

OVERVIEW

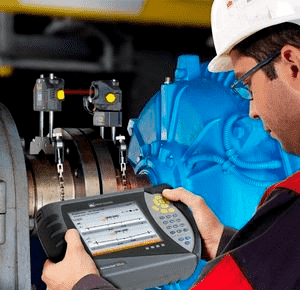

| COURSE TITLE | : | RE0242 : Machine Laser Alignment |

| COURSE DATE | : | Mar 04 - Mar 07 2024 |

| DURATION | : | 4 Days |

| INSTRUCTOR | : | Mr. Dimitry Rovas Days |

| VENUE | : | Istanbul, Turkey |

| COURSE FEE | : | $ 5000 |

| Request For Course | ||

OTHER SCHEDULED DATES

| Date | : | Jun 03 - Jun 06 (4 Days) | Location | : | Al Khobar, KSA | Classroom Fee (US$) | : | $ 4500 | Course Info |

| Date | : | Sep 02 - Sep 05 (4 Days) | Location | : | Dubai, UAE | Classroom Fee (US$) | : | $ 4500 | Course Info |

| Date | : | Dec 09 - Dec 12 (4 Days) | Location | : | Abu Dhabi, UAE | Classroom Fee (US$) | : | $ 4500 | Course Info |

Course Description

This practical and highly-interactive course includes practical sessions and exercises. Theory learnt will be applied using our state-of-the-art simulators. This course is designed to provide participants with a detailed and up-to-date overview of laser alignment. It covers the laser alignment techniques and maximum utilization of existing FixturLaser functions; the importance of proper shaft alignment and the symptoms of misalignment; the foundations, baseplate, piping effects and various types of couplings, flexible and rigid couplings; the alignment and coupling tolerances and the preliminary alignment checks; the different lasers and detectors systems and the advantages of laser alignment; and laser alignment procedures, mathematical relationships and ?on board? laser alignment calculations. At the end of the course, participants will be able to carryout adjustments for thermal growth; identify ?hot? alignment versus ?cold? alignment and moving machinery in the field; evaluate alignment considerations for specific equipment including electric motors, pumps, gear boxes, compressors, cooling towers, blowers & fans & internal combustion engines; and prevent misalignment severity and vibrations caused by misalignment.

TRAINING METHODOLOGY

This interactive training course includes the following training methodologies as a percentage of the total tuition hours

LecturesWorkshops & Work Presentations

Case Studies & Practical Exercises

Videos, Software & Simulators

In an unlikely event, the course instructor may modify the above training methodology before or during the course for technical reasons.

VIRTUAL TRAINING (IF APPLICABLE)

If this course is delivered online as a Virtual Training, the following limitations will be applicable

| Certificates | : | Only soft copy certificates will be issued to participants through Haward’s Portal. This includes Wallet Card Certificates if applicable |

| Training Materials | : | Only soft copy Training Materials (PDF format) will be issued to participant through the Virtual Training Platform |

| Training Methodology | : | 80% of the program will be theory and 20% will be practical sessions, exercises, case studies, simulators or videos |

| Training Program | : | The training will be for 4 hours per day starting at 09:30 and ending at 13:30 |

| H-STK Smart Training Kit | : | Not Applicable |

| Hands-on Practical Workshops | : | Not Applicable |

| Site Visit | : | Not Applicable |

| Simulators | : | Only software simulators will be used in the virtual courses. Hardware simulators are not applicable and will not be used in Virtual Training |

RELATED COURSES

RE0096 : Advanced Inspection & Performance Evaluation of Rotating Equipment including Turbine Maintenance

- Date : May 19 -May 23 / 3 Days

- Location : Doha, Qatar

- Course Details Register

RE0190 : Practical Machinery Vibration Monitoring, Analysis & Predictive Maintenance: Vibration Techniques

- Date : May 20 -May 23 / 3 Days

- Location : Dubai, UAE

- Course Details Register

RE0045 : Material Cataloguing, Specifications, Handling & Storage

- Date : May 20 -May 23 / 3 Days

- Location : Dubai, UAE

- Course Details Register

RE0210 : Excellence in Maintenance & Reliability Management: Advanced Techniques in Maintenance Management

- Date : May 13 -May 16 / 3 Days

- Location : Doha, Qatar

- Course Details Register