COURSE OVERVIEW

MECHANICAL ENGINEERING

OVERVIEW

| COURSE TITLE | : | ME0447 : Rotating Equipment Selection, Operation, Maintenance, Inspection & Troubleshooting |

| COURSE DATE | : | Aug 12 - Aug 15 2024 |

| DURATION | : | 4 Days |

| INSTRUCTOR | : | Mr. Andrew Ladwig Days |

| VENUE | : | Istanbul, Turkey |

| COURSE FEE | : | $ 5000 |

| Register For Course | ||

OTHER SCHEDULED DATES

| Date | : | Feb 12 - Feb 15 (4 Days) | Location | : | Dubai, UAE | Classroom Fee (US$) | : | $ 4500 | Course Info |

| Date | : | May 06 - May 09 (4 Days) | Location | : | Abu Dhabi, UAE | Classroom Fee (US$) | : | $ 4500 | Course Info |

| Date | : | Nov 25 - Nov 28 (4 Days) | Location | : | Al Khobar, KSA | Classroom Fee (US$) | : | $ 4500 | Course Info |

Course Description

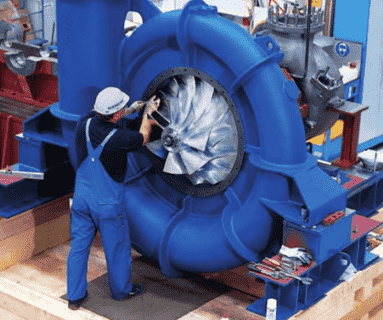

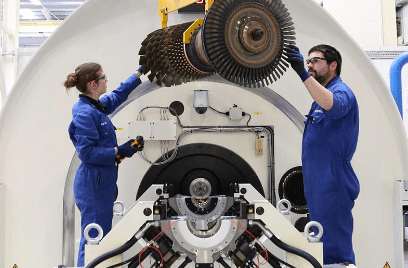

This practical and highly-interactive course includes various practical sessions and exercises. Theory learnt will be applied using our state-of-theart simulators. The course is designed to cover the machinery application. This includes the selection, operation, maintenance, inspection and troubleshooting of the various types of machinery such as compressors, pumps, motors, turbines, turbo-expanders, gears and transmission equipment. The course will feature a unique blend of practical application experience and basic analysis methods. Its aim is to convey a thorough understanding of machinery operating principles, equipment and specific operations. The course will cover the principal machines represented at a large number of plants. There will be a thorough examination of basic operating concepts, application ranges, selection criteria, maintenance, inspection and vulnerabilities of certain types of equipment. The course will also review the short-cut selection and sizing methods for fluid machinery. Upon the successful completion of this course, participants will have gained an understanding of the 12 principal types of machinery used in industry. They will understand the differences between electric motors, design peculiarities, advantages and disadvantages of different types of gears, operating principles of gas turbines and reciprocating gas engines.The course will convey an understanding of impulse vs. reaction turbines, insights into application ranges, limitations, maintenance and operability constraints for different kinds of pumps, compressors and dynamic gas machinery such as turbo-machinery as opposed to displacement machinery.

TRAINING METHODOLOGY

This interactive training course includes the following training methodologies as a percentage of the total tuition hours

LecturesWorkshops & Work Presentations

Case Studies & Practical Exercises

Videos, Software & Simulators

In an unlikely event, the course instructor may modify the above training methodology before or during the course for technical reasons.

VIRTUAL TRAINING (IF APPLICABLE)

If this course is delivered online as a Virtual Training, the following limitations will be applicable

| Certificates | : | Only soft copy certificates will be issued to participants through Haward’s Portal. This includes Wallet Card Certificates if applicable |

| Training Materials | : | Only soft copy Training Materials (PDF format) will be issued to participant through the Virtual Training Platform |

| Training Methodology | : | 80% of the program will be theory and 20% will be practical sessions, exercises, case studies, simulators or videos |

| Training Program | : | The training will be for 4 hours per day starting at 09:30 and ending at 13:30 |

| H-STK Smart Training Kit | : | Not Applicable |

| Hands-on Practical Workshops | : | Not Applicable |

| Site Visit | : | Not Applicable |

| Simulators | : | Only software simulators will be used in the virtual courses. Hardware simulators are not applicable and will not be used in Virtual Training |

RELATED COURSES

ME0933 : Hydraulic Tools & Fitting Certification

- Date : May 20 -May 24 / 3 Days

- Location : Abu Dhabi, UAE

- Course Details Register

ME0398 : Pumps, Compressors, Turbines & Troubleshooting

- Date : May 12 -May 16 / 3 Days

- Location : Doha, Qatar

- Course Details Register

ME0138 : Application of Standards in Boiler, Pressure Vessel & Piping Systems

- Date : Jul 22 -Jul 25 / 3 Days

- Location : Abu Dhabi, UAE

- Course Details Register

ME0615 : Pumps & Compressors: Operation, Maintenance & Troubleshooting

- Date : May 13 -May 16 / 3 Days

- Location : Abu Dhabi, UAE

- Course Details Register