COURSE OVERVIEW

MECHANICAL ENGINEERING

OVERVIEW

| COURSE TITLE | : | ME0990 : Bolted Flange & Gasket Design & Stress Analysis (ASME/ANSI) |

| COURSE DATE | : | Oct 14 - Oct 17 2024 |

| DURATION | : | 4 Days |

| INSTRUCTOR | : | Mr. Rod Larmour Days |

| VENUE | : | Dubai, UAE |

| COURSE FEE | : | $ 4500 |

| Register For Course Outline | ||

OTHER SCHEDULED DATES

| Date | : | Apr 15 - Apr 18 (4 Days) | Location | : | Al Khobar, KSA | Classroom Fee (US$) | : | $ 4500 | Course Info |

| Date | : | Jul 08 - Jul 11 (4 Days) | Location | : | Istanbul, Turkey | Classroom Fee (US$) | : | $ 5000 | Course Info |

Course Description

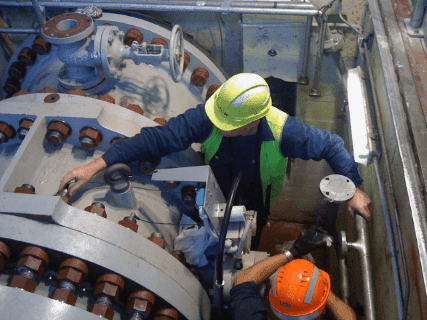

This practical and highly-interactive course includes practical sessions and exercises. Theory learnt will be applied using our state-of-the-art simulators. In this course, we shall be analyzing the riveted and bolted joints used in the oil refineries for jointing of pipes & plates, for the blinding of pipes, pressure vessels and heat exchangers. The selection of pipe flanges is well documented in the ASME code and is fairly straight forward when pressures and temperatures are known. Use of the code makes the specific selection of components such as flanged valves, meters, pumps and compressors also fairly straight forward in most instances. As a piping designer or engineer it is, however, essential to have an understanding of the flange joint make-up as a unit. To this end, it is essential to understand the meaning of bolt preload and its importance in the flange joint, when considering external loadings due to (1) internal pressure, (2) cyclic conditions- leading to possible fatigue, (3) the effect of temperature, (4) shear and bending loads, and (5) vibration.The aspect of fatigue loadings will be covered, however in practice the cyclic conditions encountered can be extremely difficult to estimate. An example of a pipeline in Alaska will be discussed in this regard. Sometimes, at best, a designer/ engineer can only make assumptions (and judgments based on experience), regarding expected vibration. Accurate bending and shear loads on flange joints can sometimes only be established from a pipe stress analysis programme.Circular flat plates will be analyzed and compared to blind flanges, and pressure vessel heat exchanger applications. link to course overview PDF

TRAINING METHODOLOGY

This interactive training course includes the following training methodologies as a percentage of the total tuition hours

LecturesWorkshops & Work Presentations

Case Studies & Practical Exercises

Videos, Software & Simulators

In an unlikely event, the course instructor may modify the above training methodology before or during the course for technical reasons.

VIRTUAL TRAINING (IF APPLICABLE)

If this course is delivered online as a Virtual Training, the following limitations will be applicable

| Certificates | : | Only soft copy certificates will be issued to participants through Haward’s Portal. This includes Wallet Card Certificates if applicable |

| Training Materials | : | Only soft copy Training Materials (PDF format) will be issued to participant through the Virtual Training Platform |

| Training Methodology | : | 80% of the program will be theory and 20% will be practical sessions, exercises, case studies, simulators or videos |

| Training Program | : | The training will be for 4 hours per day starting at 09:30 and ending at 13:30 |

| H-STK Smart Training Kit | : | Not Applicable |

| Hands-on Practical Workshops | : | Not Applicable |

| Site Visit | : | Not Applicable |

| Simulators | : | Only software simulators will be used in the virtual courses. Hardware simulators are not applicable and will not be used in Virtual Training |

RELATED COURSES

ME0976 : Screw Compressor Theory and Troubleshooting

- Date : May 13 -May 16 / 3 Days

- Location : Dubai, UAE

- Course Details Register

ME0138 : Application of Standards in Boiler, Pressure Vessel & Piping Systems

- Date : Jul 22 -Jul 25 / 3 Days

- Location : Abu Dhabi, UAE

- Course Details Register

ME0933 : Hydraulic Tools & Fitting Certification

- Date : May 20 -May 24 / 3 Days

- Location : Abu Dhabi, UAE

- Course Details Register

ME0615 : Operation, Maintenance & Troubleshooting of Pumps & Compressors

- Date : May 12 -May 16 / 3 Days

- Location : Istanbul, Turkey

- Course Details Register