COURSE OVERVIEW

FACILITY INTEGRITY, INSPECTION, METALLURGY & CORROSION ENGINEERING

OVERVIEW

| COURSE TITLE | : | FE0015 : Piping Mechanical Design & Specification |

| COURSE DATE | : | Oct 13 - Oct 17 2024 |

| DURATION | : | 5 Days |

| INSTRUCTOR | : | Mr. Andrew Ladwig Days |

| VENUE | : | Doha, Qatar |

| COURSE FEE | : | $ 6000 |

| Register For Course | ||

OTHER SCHEDULED DATES

| Date | : | Apr 22 - Apr 25 (4 Days) | Location | : | Abu Dhabi, UAE | Classroom Fee (US$) | : | $ 4500 | Course Info |

| Date | : | Jul 08 - Jul 11 (4 Days) | Location | : | Al Khobar, KSA | Classroom Fee (US$) | : | $ 4500 | Course Info |

Course Description

This practical highly-interactive course includes various practical sessions and exercises. Theory learnt will be applied using our state-of-the-art simulators. This course is designed to provide participants with a detailed and up-to-date overview of Piping Mechanical Design and Specification. It covers the principles of piping mechanical design and the role of mechanical design in piping systems; the codes and standards relevant to piping mechanical design and considerations for various process conditions and materials; the material selection criteria based on process conditions and fluid properties; the piping material specifications and standards; the corrosion resistance and material compatibility considerations, temperature and pressure limitations for different materials; and the documentation and traceability requirements for piping materials. Further, the course will also discuss the types of loads acting on piping systems; the methods for determining loads and stresses; the stress categories and allowable stress analysis, thermal expansion, contraction analysis and software tools for stress analysis; the pipe wall thickness calculation, pressure design thickness calculation methods, accounting for corrosion allowances and mill tolerance; the external pressure design calculations and verification of pipe wall thickness using applicable codes and standards; the piping supports and restraints; the load distribution and selection of support types; the design considerations for spring hangers, snubbers and restraints; and the analysis of piping systems with variable loads and movements.During this interactive course, participants will learn the pipe stress analysis, load case development and analysis procedure, flexibility analysis and pipe displacement evaluation; the piping vibration analysis and mitigation measures for addressing excessive vibration; the piping component design and selection, expansion joints and flexible joints; and the piping specification development and documentation.

TRAINING METHODOLOGY

This interactive training course includes the following training methodologies as a percentage of the total tuition hours

LecturesWorkshops & Work Presentations

Case Studies & Practical Exercises

Videos, Software & Simulators

In an unlikely event, the course instructor may modify the above training methodology before or during the course for technical reasons.

VIRTUAL TRAINING (IF APPLICABLE)

If this course is delivered online as a Virtual Training, the following limitations will be applicable

| Certificates | : | Only soft copy certificates will be issued to participants through Haward’s Portal. This includes Wallet Card Certificates if applicable |

| Training Materials | : | Only soft copy Training Materials (PDF format) will be issued to participant through the Virtual Training Platform |

| Training Methodology | : | 80% of the program will be theory and 20% will be practical sessions, exercises, case studies, simulators or videos |

| Training Program | : | The training will be for 4 hours per day starting at 09:30 and ending at 13:30 |

| H-STK Smart Training Kit | : | Not Applicable |

| Hands-on Practical Workshops | : | Not Applicable |

| Site Visit | : | Not Applicable |

| Simulators | : | Only software simulators will be used in the virtual courses. Hardware simulators are not applicable and will not be used in Virtual Training |

RELATED COURSES

FE0630 : Material Certification Management

- Date : May 12 -May 16 / 3 Days

- Location : Istanbul, Turkey

- Course Details Register

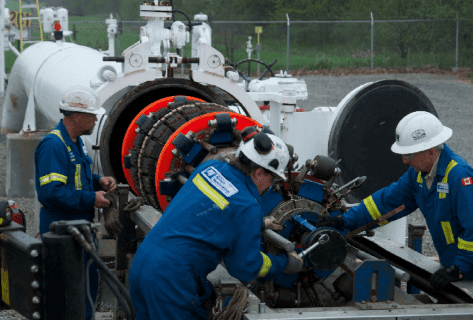

FE0200 : Pipeline Pigging - Technical & Operational Aspects

- Date : May 20 -May 23 / 3 Days

- Location : Istanbul, Turkey

- Course Details Register

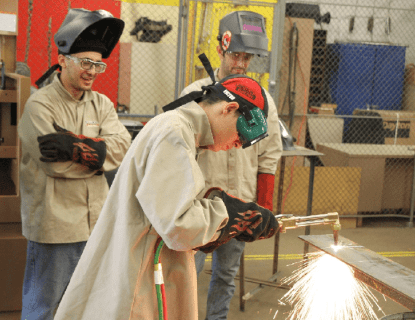

FE0430 : Welding Engineering: Welding, Fabrication and Inspection (AWS, ASME and API Codes)

- Date : May 20 -May 23 / 3 Days

- Location : Dubai, UAE

- Course Details Register

FE0191 : Essential PIMS (Pipeline Integrity Management System)

- Date : May 13 -May 16 / 3 Days

- Location : Dubai, UAE

- Course Details Register