COURSE OVERVIEW

ANALYTICAL LABORATORY, ANALYZERS, R&D AND R&T ENGINEERING

OVERVIEW

| COURSE TITLE | : | LE0200 : Process Analyzer Technology |

| COURSE DATE | : | Dec 09 - Dec 12 2024 |

| DURATION | : | 4 Days |

| INSTRUCTOR | : | Mr. Dirk Horst Days |

| VENUE | : | Abu Dhabi, UAE |

| COURSE FEE | : | $ 4500 |

| Register For Course | ||

OTHER SCHEDULED DATES

| Date | : | Jun 03 - Jun 06 (4 Days) | Location | : | Istanbul, Turkey | Classroom Fee (US$) | : | $ 5000 | Course Info |

| Date | : | Sep 02 - Sep 05 (4 Days) | Location | : | Dubai, UAE | Classroom Fee (US$) | : | $ 4500 | Course Info |

Course Description

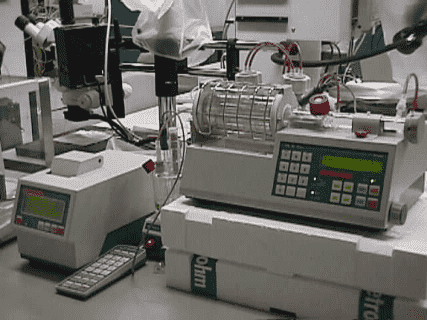

This practical, highly-interactive course includes practical sessions and exercises where participants will visit the laboratory and they will be introduced to various lab instruments and process analyzers. Practical sessions will be performed using one instrument in order to apply the theory learnt in the class. The analysis of process liquids and gases in today?s oil, gas and chemicals industries requires accurate knowledge of composition and make up of process fluids. This in turn means accurate measurement of those compositions. Without measurement there can be no control and no information as to the state of the process. Similarly, we have no way of knowing if we are causing environmental damage without this type of monitoring. With the advancement in computer applications and electronics, analyzers have gained popularity in recent years. They have taken the spot sampling capability of a laboratory and converted into a continuous sampling system. With continuous sampling, the process variable is being analyzed on a continuous basis with a much faster update time. Faster update time has given the analyzer the ability to be used for control purposes. This course is designed to cover the purpose of analyzer systems, how they are selected and their installation and maintenance. Course participants will learn how a sample is conditioned so the analyzer will give a representative reading of the component that is of interest in the process.The course describes the major types of process analyzers and the principles behind the selection, construction and operation of each analyzer. It covers multiple measurement techniques ranging from physical, thermal, electrical, and optical techniques through those utilized in electrochemistry, chromatography and spectroscopy. It also touches on maintenance, system packaging and system errors consideration.

TRAINING METHODOLOGY

This interactive training course includes the following training methodologies as a percentage of the total tuition hours

LecturesWorkshops & Work Presentations

Case Studies & Practical Exercises

Videos, Software & Simulators

In an unlikely event, the course instructor may modify the above training methodology before or during the course for technical reasons.

VIRTUAL TRAINING (IF APPLICABLE)

If this course is delivered online as a Virtual Training, the following limitations will be applicable

| Certificates | : | Only soft copy certificates will be issued to participants through Haward’s Portal. This includes Wallet Card Certificates if applicable |

| Training Materials | : | Only soft copy Training Materials (PDF format) will be issued to participant through the Virtual Training Platform |

| Training Methodology | : | 80% of the program will be theory and 20% will be practical sessions, exercises, case studies, simulators or videos |

| Training Program | : | The training will be for 4 hours per day starting at 09:30 and ending at 13:30 |

| H-STK Smart Training Kit | : | Not Applicable |

| Hands-on Practical Workshops | : | Not Applicable |

| Site Visit | : | Not Applicable |

| Simulators | : | Only software simulators will be used in the virtual courses. Hardware simulators are not applicable and will not be used in Virtual Training |

RELATED COURSES

LE0430 : Modern Laboratory Safety & Health

- Date : May 20 -May 23 / 3 Days

- Location : Doha, Qatar

- Course Details Register

LE0140 : Modern Laboratory Management: Effective Management of the Chemical Analysis Support

- Date : May 13 -May 16 / 3 Days

- Location : Al Khobar, KSA

- Course Details Register