COURSE OVERVIEW

PROCESS & CHEMICAL ENGINEERING

OVERVIEW

| COURSE TITLE | : | PE0095 : Catalyst Material Handling: Loading, Unloading, Oxidation, Reduction & Techniques |

| COURSE DATE | : | Mar 03 - Mar 07 2024 |

| DURATION | : | 5 Days |

| INSTRUCTOR | : | Mr. Mervyn Frampton Days |

| VENUE | : | Dubai, UAE |

| COURSE FEE | : | $ 5500 |

| Request For Course Outline | ||

OTHER SCHEDULED DATES

| **---- No Other Scheduled Dates ----** |

Course Description

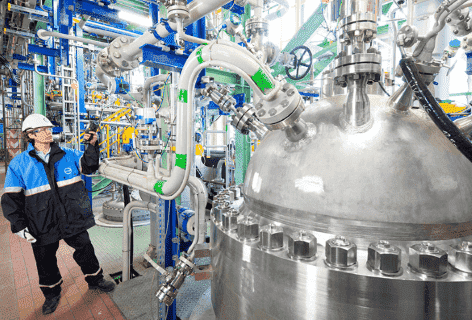

This practical and highly-interactive course includes various practical sessions and exercises. Theory learnt will be applied using one of our stateof-the-art simulators. This course is designed to provide participants with a detailed and up-to-date overview on catalyst material handling, loading, unloading, oxidation, reduction and technique. It covers the preparation of catalyst change plan; executing the catalyst project efficiently and safely; the catalyst change operation main requirement; the work in inert and toxic atmospheres plus hot and hostile environments; the reactor cooling utilizing a proprietary liquid nitrogen system; the unloading and loading of catalyst under inert or normal atmospheres; the dense phase loading systems; and the innovative, purpose built-equipment ensuring low catalyst attrition rate. Further, the course also covers the catalyst sampling and particle measurement; the vacuum unloading with closed loop nitrogen re-circulation; the catalyst transportation, storage & containment (un approved); the tubular reformer loadings using unidense? loading and conventional techniques; the pre-sulphiding (DMDS injection); the metals reclamation and disposal of materials; the shutdown planning, coordination and execution; the edge equipment; the modifications for catalytic reactors, vessels on a blinds to blinds? basis; and the confined space and inert/toxic entry operations link to course overview PDF

TRAINING METHODOLOGY

This interactive training course includes the following training methodologies as a percentage of the total tuition hours

LecturesWorkshops & Work Presentations

Case Studies & Practical Exercises

Videos, Software & Simulators

In an unlikely event, the course instructor may modify the above training methodology before or during the course for technical reasons.

VIRTUAL TRAINING (IF APPLICABLE)

If this course is delivered online as a Virtual Training, the following limitations will be applicable

| Certificates | : | Only soft copy certificates will be issued to participants through Haward’s Portal. This includes Wallet Card Certificates if applicable |

| Training Materials | : | Only soft copy Training Materials (PDF format) will be issued to participant through the Virtual Training Platform |

| Training Methodology | : | 80% of the program will be theory and 20% will be practical sessions, exercises, case studies, simulators or videos |

| Training Program | : | The training will be for 4 hours per day starting at 09:30 and ending at 13:30 |

| H-STK Smart Training Kit | : | Not Applicable |

| Hands-on Practical Workshops | : | Not Applicable |

| Site Visit | : | Not Applicable |

| Simulators | : | Only software simulators will be used in the virtual courses. Hardware simulators are not applicable and will not be used in Virtual Training |

RELATED COURSES

PE0221 : Operation of Process Equipment: Fired Heaters, Air Coolers, Heat Exchangers, Pumps, Compressors, Crude Desalter, Pressure Vessels & Valves

- Date : May 12 -May 16 / 3 Days

- Location : Dubai, UAE

- Course Details Register

PE0625 : Introduction to Polypropylene Technology

- Date : May 20 -May 23 / 3 Days

- Location : Istanbul, Turkey

- Course Details Register

PE0450 : Plastic Additives Selection, Application & Troubleshooting

- Date : May 20 -May 23 / 3 Days

- Location : Doha, Qatar

- Course Details Register

PE0620 : Polyethylene & Polypropylene Manufacturing & Process Troubleshooting

- Date : May 13 -May 16 / 3 Days

- Location : Al Khobar, KSA

- Course Details Register